Case Study

Lambda Function

Roles

CTO

Product Management

Overview:

Lambda Function is a cutting-edge Intelligent Control System (ICS) that enhances machining autonomy through Artificial Intelligence (AI). Their platform helps CNC machine operators and NC programmers improve efficiency and reduce human intervention by recommending optimal machining strategies and monitoring tool life in real time.

Problem:

Lambda Function’s goal was to enable Level 5 machining autonomy, where CNC machines could make decisions based on CAD drawings without human intervention. The project required:

Developing a highly integrated AI system to recommend optimal machining strategies.

Implementing real-time load monitoring to prevent issues like overloads and tool breakages.

Ensuring the system could provide actionable insights for continuous improvement on the shop floor.

Solution:

During my contract as Interim Technology Lead, I worked with Lambda Function to guide the team through the development and operationalization of the project, including AI-assisted features such as:

Generative Programming: Recommends machining strategies, cutting tools, and parameters based on part geometry and material physics.

Real-Time Load and Tool Life Monitoring: Detects anomalies in machine behavior, recommends cutting tool changes, and prevents tool wastage or breakage.

Continuous Kaizen Insights: Automatically generates insights to support continuous improvement (kaizen) efforts on the shop floor.

Adverse Event Avoidance: Recommends adjustments to feeds and speeds to avoid potential risks in the machining process.

I was responsible for the following:

Creating Standard Operating Procedures (SOPs): Designed processes for project management, agile methodologies, and communication tools to streamline workflow.

Aligning Engineering Teams: Worked with machine learning, API design, and frontend development teams to ensure consistent progress and alignment with technical objectives.

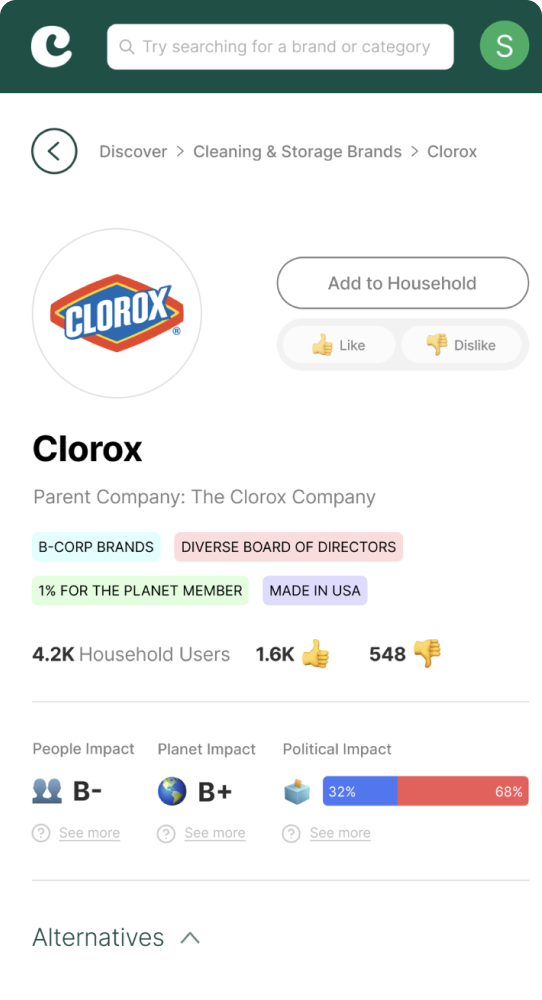

Conducting a Product Design Sprint: Led a 5-day workshop with key stakeholders to define user interaction with Lambda's platform, ensuring that the product met user needs and expectations.

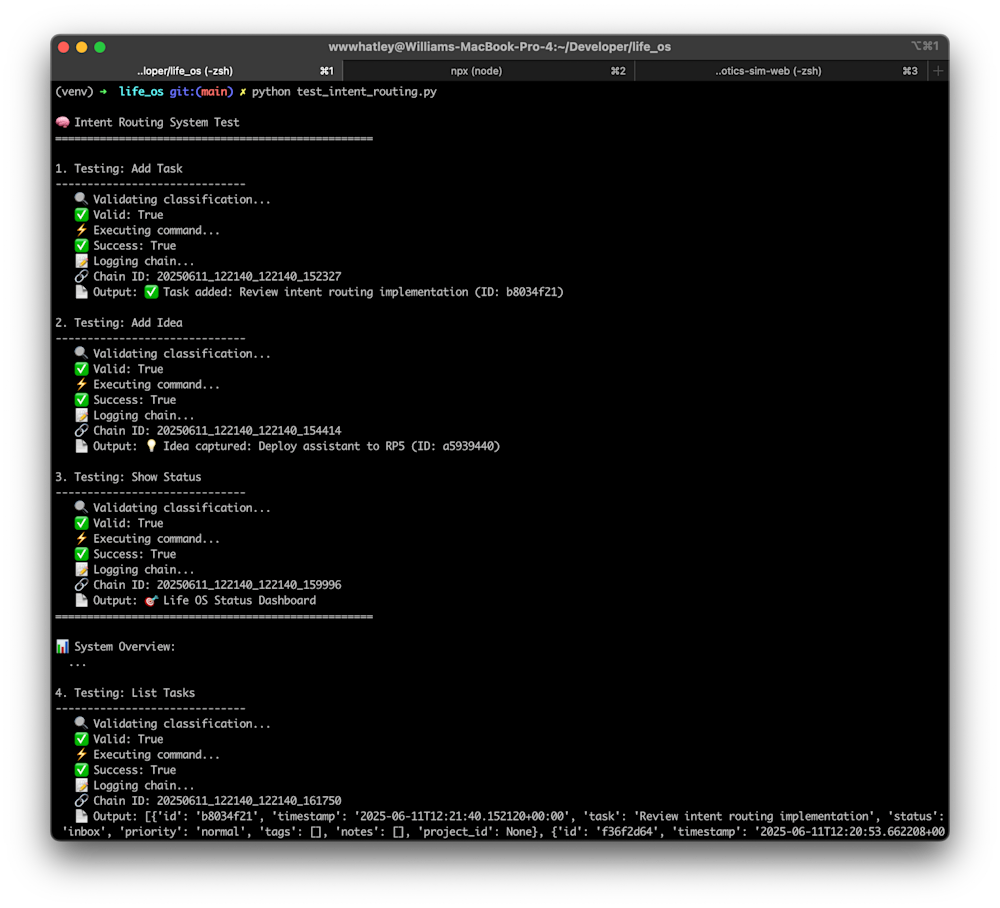

Overseeing Development: Reviewed pull requests (PRs), ensured smooth productization, and implemented CI/CD pipelines, cloud infrastructure, and quality controls.

Technologies Used:

- Machine Learning / Artificial Intelligence

- CI/CD Pipelines

- Cloud Infrastructure

- Project Management Tools (Agile Methodologies)

Outcome:

Lambda Function successfully advanced through its R&D phase. The product has proven its value by delivering 10x+ ROI for manufacturers, driving:

Higher machine uptime and reduced downtime

Lower rework & scrap through smarter recommendations

Optimized cutting tool usage to reduce waste and cost

Increased staff productivity through smarter automation

Significant reduction in programming time, from weeks to days

Improved forecasting of machining costs and potential issues

The Lambda Function platform is now helping precision component manufacturers achieve greater operational efficiency, with its ability to forecast machining costs, optimize tool life, and support continuous improvement initiatives.

Work

Recent products & orgs

Contact

Let’s build something together

If you’re ready to take your project to the next level, contact me today. I’m always excited to discover new projects, and connect with talented people who have a vision for their business. Drop me a line and I’ll get back to you.